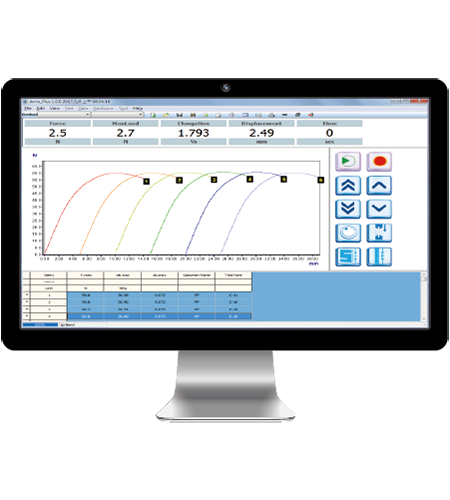

1.Data sample rate faster can be set up to 1200 Hz.

2.Operation method: By keyboard and mouse control test, can also through up and down button to adjust the fixture position.

3.Compatible with Window 7 /8 /10 systems.

4.Software has multi-languages with Chinese, English, Japanese, Korean, Spanish, Polish and Portuguese display.

5.Operating mode: TCP / IP interface, two-way transmission, the computer directly control the machine action.

6.Can import multiple test data display simultaneously.

7.Unit selection can be Metric unit and Imperial units.

8.Form flexibility, self-planning information analysis.

9.Data name can be self-set and can self-defined formula

10.Test Screen can be selected data display, graphic display or simultaneous display.

11.Data processing: store, call, list, statistical comparison, etc.

12.Graph X-Y axis physical quantity adjustment, graph-specific mark, interval mark, slope and son on.

13.Test tensile, compression, bending, peeling, spring, creep and other tests.

14.Software protection: Overload, over -displacement, over-time protection.

15.Variety of test actions, ex. reciprocation, creep, hold tensile (compression), test pause, slip test, etc.

16.Modularization of specimen setting, providing easy to set specimen.

17.Modularization of test conditions to reduce artificial setting negligence and error.

18.Key data capture, can set the upper and lower limits of test data specifications.

19.Support multiple sets of I / O signals, increase testing mechanism